5S Lean 5S Principles in the Workplace SafetyCulture

5S is a core methodology to lean manufacturing which was first implemented in Toyota's Production System (TPS) in the 60s. This method aims to help factories achieve operational excellence and reduce waste consistently. Some of the benefits of implementing this approach are: Higher quality products Reduced production costs Productivity increase

Lean Manufacturing 5S Lean six sigma, Lean manufacturing, Change

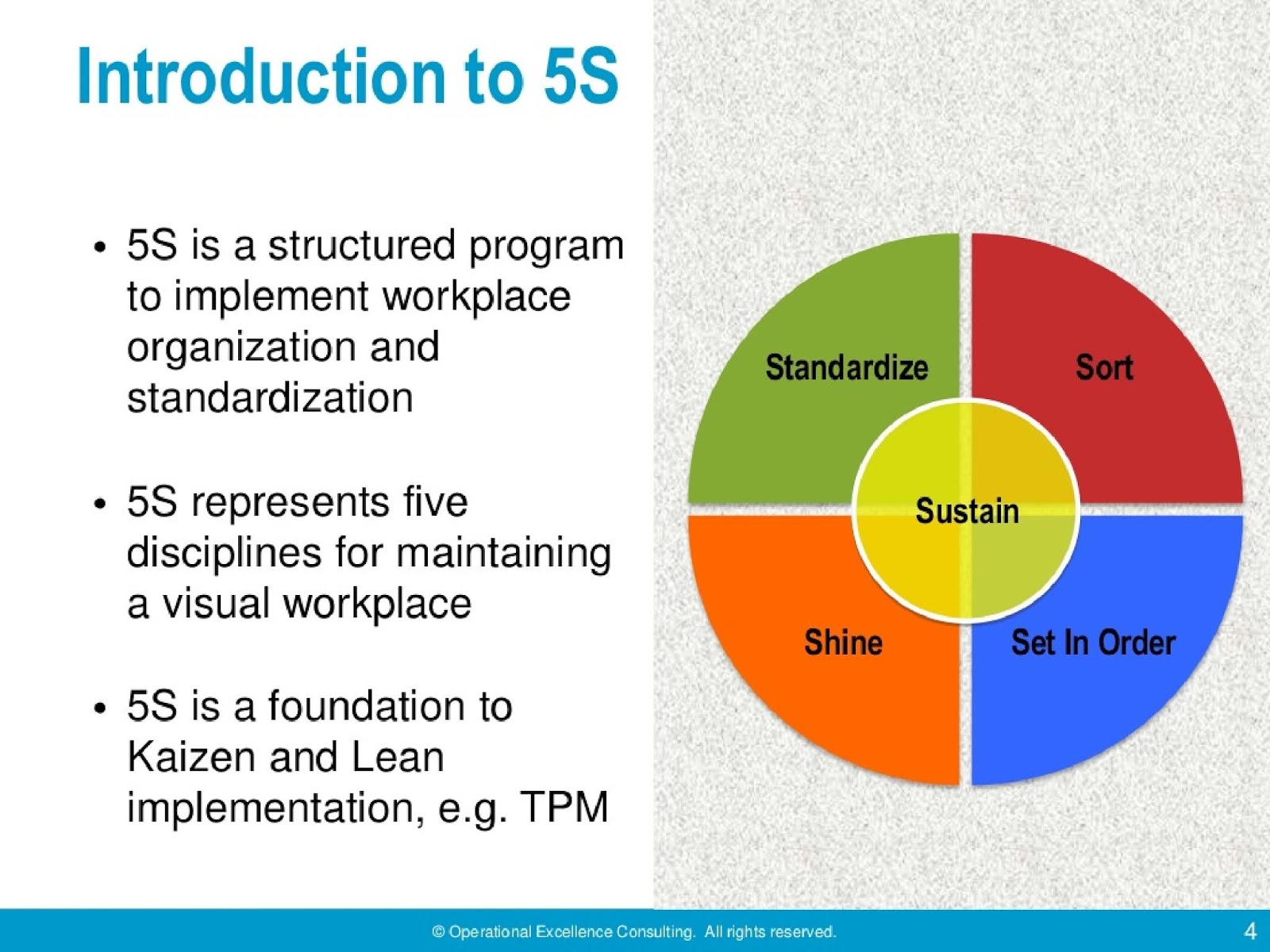

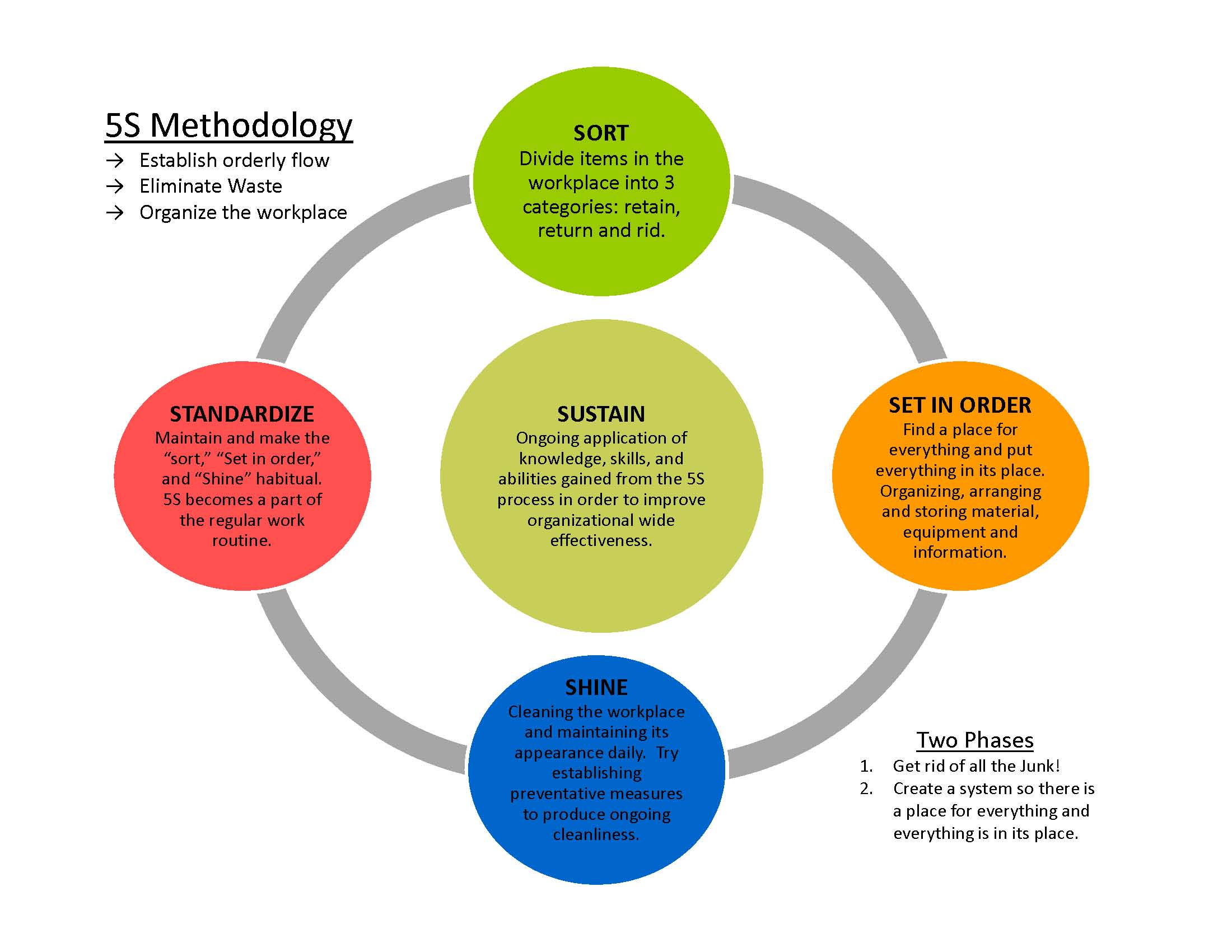

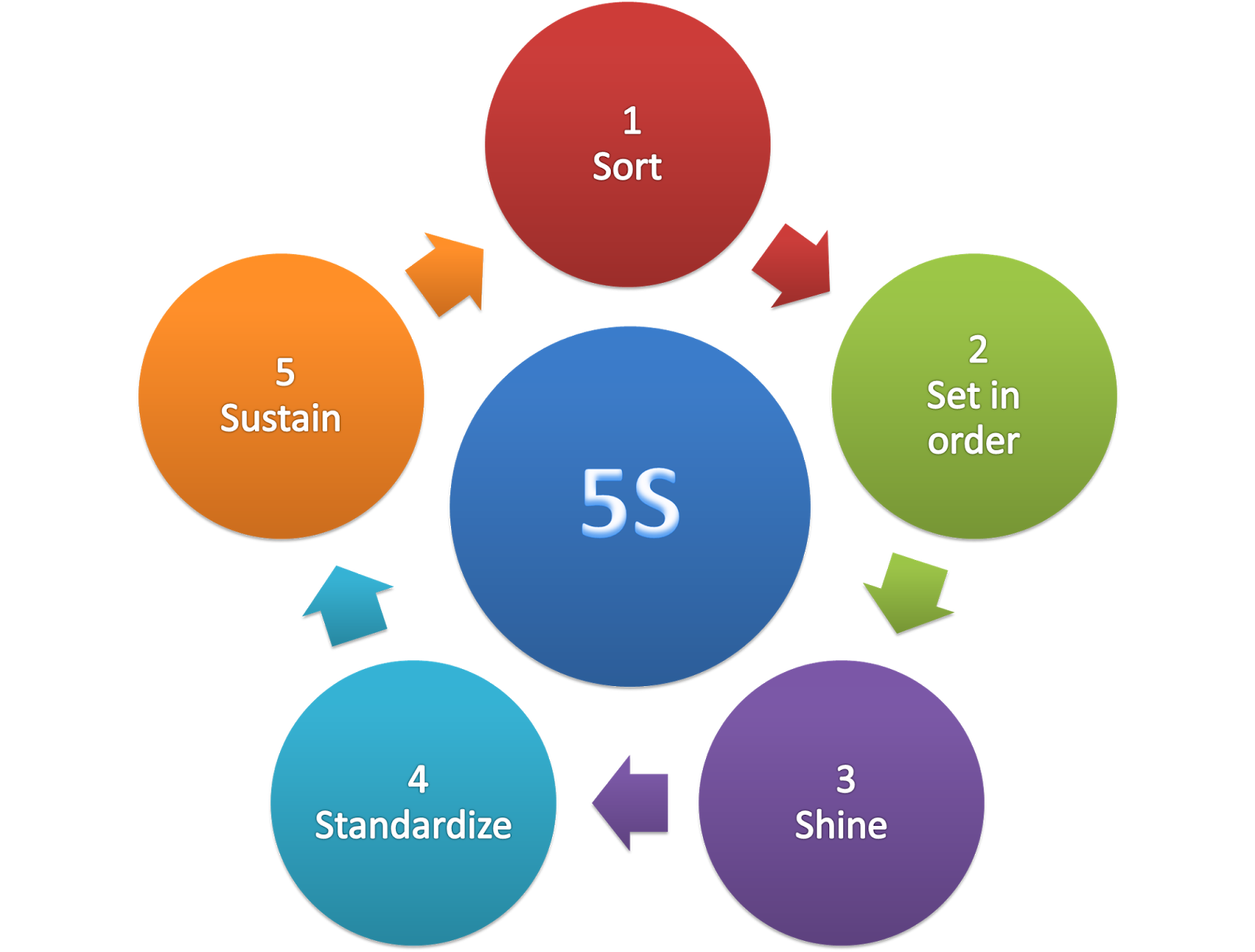

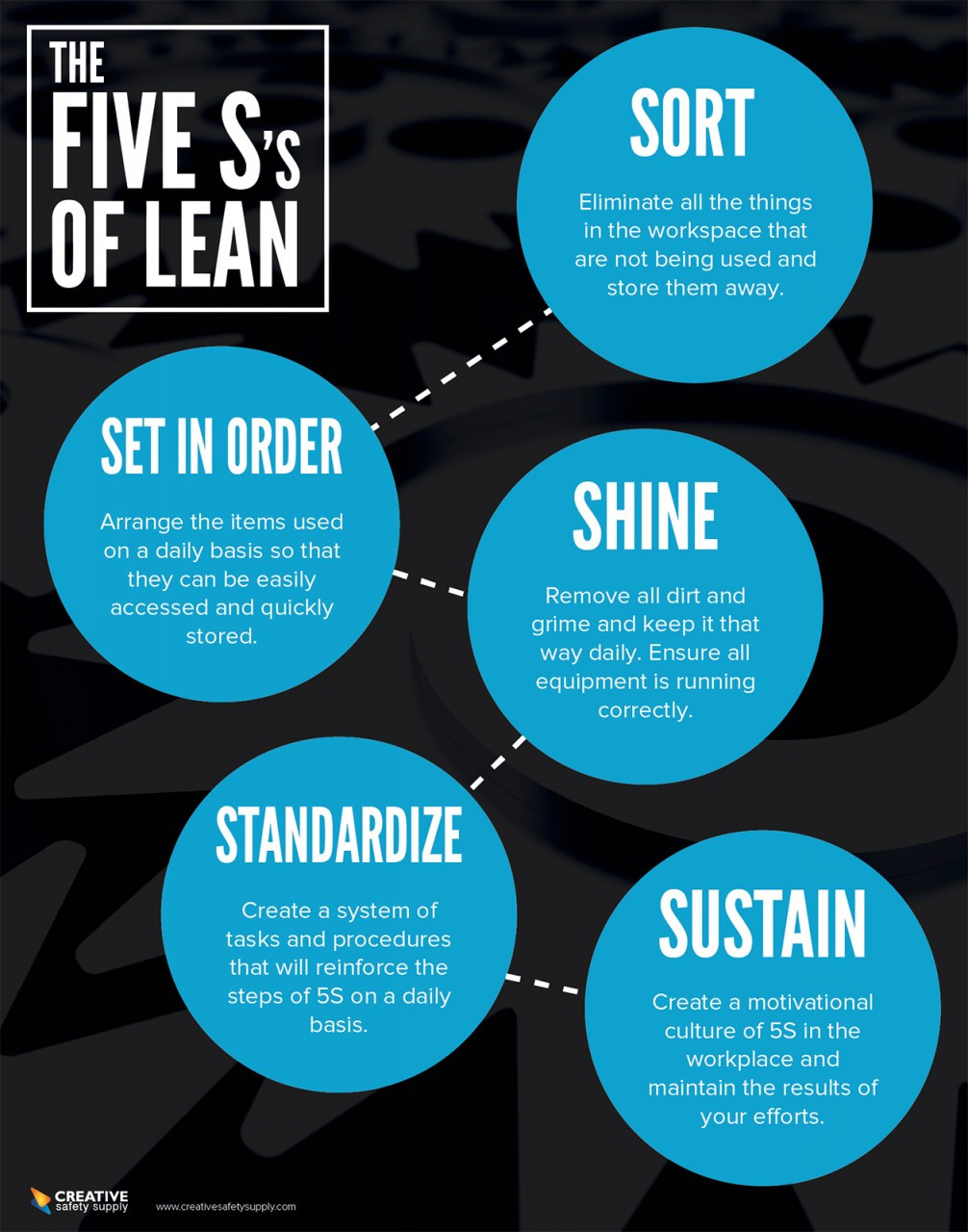

In English, the 5S's are: Sort, Straighten, Shine, Standardize, and Sustain. 5S serves as a foundation for deploying more advanced lean production tools and processes. What Is the 5S Methodology? Why Is 5S Important in Manufacturing? What Are the 5 Benefits of a 5S System? Sort (Seiri) Straighten (Seiton) Shine (Seisou) Standardize (Seiketsu)

What is Lean 5S Methodology Training & Overview Lean Smarts

5S methodology. One of the many tools in the Lean toolbox is the 5S methodology. Originating from a Japanese management philosophy, the 5S methodology refers to the five Japanese words which describe cleaning or tidying up. Keep in mind 5S is actually more than a tool, form it's Japanese heritage it also reflects a mindset, that of an.

5S Success Tips Apply It to Your Office, Home and Factory Too! AskLean

The 5S is a Lean process disciplining technique developed by Hiroyuki Hirano. 5S is made of: Seiri - sort Seiton - straighten Seiso - shine Seiketsu - standardize Shitsuke - sustain 5S focuses on specific aspects of a process, transforming a wasteful workplace into an organized, efficient, value-generating, and safe environment.

What is 5S ? Why is it so effective

The Origins of 5S - 5S & Lean Manufacturing 5S began as part of.

Lean Manufacturing Concepts 5S System A place for everything & safe

5S is the foundation of all improvements and is the key component of establishing a Visual Workplace. Both are a part of Kaizen — a system of continual improvement which is a component of lean manufacturing. A 5S program focuses on having visual order, organisation, cleanliness and standardisation. The results you can expect from a 5S program.

Tag Archives 5S Continuous Improvement Blog

Implement lean with a GE Proficy MES Manufacturing Execution System solutions demo. Enterprise manufacturing leaders boost equipment efficiency with production scheduling.

5s Lean Principles Explained John Shufeldt, MD

5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. It's designed to help build a quality work environment, both physically and mentally. The 5S philosophy applies in any work area suited for visual control and lean production.

The Lean Office The 5S Office ToughNickel

Contact us 5S - Skill Level 4: Teach & Coach Others This is an on-the-job coached course where a Senior Lean Coach will help you to teach and coach others at 5S. Available online or face-to-face. Enroll Now Want to access all our online courses and webinars all in one place?

5S DIAGRAM GRAPHIC Change Management, Project Management, Lean

Free brochures and expert advice. Buy Halls Lean-to Greenhouses now. Thousands of Satisfied Customers choose Halls Lean-to Greenhouses every year.

5S Workplace Lean Manufacturing Starbank Panel Products Ltd

5S is a lean manufacturing method that originated in Japan and is widely used in manufacturing and other industries to improve organizational processes, efficiency, and waste reduction in the workplace. The term "5S" stands for five Japanese words, each beginning with the letter "S."

Business Outsource Processing Services Five 5S Work Culture A Lean

In answer to the question 'What is 5S Lean?', it's an effective system companies use when tidying workplaces and increasing the level of organisation in a space. It works effectively in increasing the efficiency, safety and orderliness of a workplace, where equipment performs a key role in the implementation of working practices and solutions.

Lean Laboratory 5S for the Laboratory

5S is a systematic way of organizing workplaces by eliminating waste, improving flow, and reducing the number of processes where possible. It applies the five principles: Sort (seiri), Set in order (seiton), Shine (seiso), Standardize (seiketsu), and Sustain (shitsuke).

HSE Insider The 5S System

5S is a workplace organization method that uses a list of five Japanese words: seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), and shitsuke (躾). These have been translated as 'sort', 'set in order', 'shine', 'standardize', and 'sustain'. [1]

Five S's of Lean Poster (Dark) Creative Safety Supply

5S Training - Lean Training. Learn how to organise a workspace and work efficiently, effectively, and safely. Become familiarised with the concepts of red-tagging and visual management. Learn how to maintain and improve standards and implement plan development. Understand the concept of 3S shine, 4S standardise, and 5S sustain.

174 best images about Lean & 5S Workplace Organization on Pinterest

5 S in Lean: Standardize. Standardize is an essential step in the 5 Ss of lean philosophy. It means having all steps and processes done the same way every time. This helps to keep processes organized, efficient, and consistent. Standardizing ensures everyone is on the same page regarding how tasks should be completed.